Kyocera Takes Lead in Upcycling Printer Parts

Kyocera Takes Lead in Upcycling Printer Parts

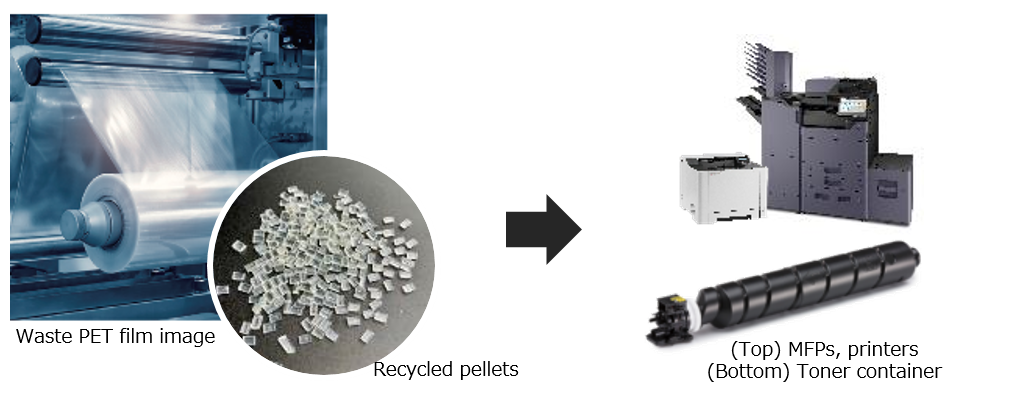

Kyocera Document Solutions Inc. announced that it has become the first company in the industry to establish technology for upcycling PET film used in manufacturing MLCC (multilayer ceramic chip capacitor), from which certain components of MFPs and printers are made.

To today, the main way of disposing PET films is thermal recycling, which however emits substantial amount of CO2 and causes heavy environmental burden. To cope with this environmental issue, Kyocera has cooperated with its Electronic Components Division and established the technology that can convert PET film into materials used in MFPs and printers.

As its initial attempt, Kyocera aims to convert the PET films into toner containers and replace all of them with recycled ones. The upcycle will make thorough use of PET films instead of discarding them directly, improving resource efficiency. In the future, Kyocera will consider expand the use of recycled materials to more parts, both internal and external, and achieve a recycled rate of 50% per product.

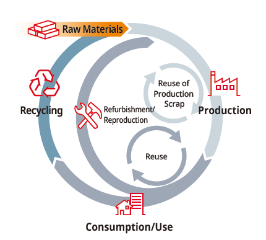

Kyocera applies three principles of “Living Together” throughout all its corporate activities: coexistence with society, coexistence with the world, and coexistence with nature. Guided by these principles, Kyocera has been striving to pursue both environmental and economic performance, which is in line with the growing demands for circular economy. The breakthrough in upcycling, together with other initiatives aiming to achieve zero waste, demonstrates Kyocera’s consistent effort toward sustainability and contribution to society.

Related:

- Kyocera Reports Robust Printing Unit Performance in Q1 2025

- Kyocera Launches New Ecosys A4 Printers

- Kyocera Introduces WebAR technology

- Kyocera Inkjet Division Appoints New Senior Director

Comment:

Please leave your comment below about the news: Kyocera Takes Lead in Upcycling Printer Parts.

Leave a Comment

Want to join the discussion?Feel free to contribute!