Chips Codes Cartridges and Printers

Chips Codes Cartridges and Printers

“It was the simple code, a key to communication between cartridges and printers.” Before I knew about serial numbers, I never could have imagined a simple code could dominate the future development of the aftermarket.

Ever since the arrival of the desktop printing aftermarket, there have been complaints about replacement cartridges used or, in most cases, unable to be used in printers. Consumers blamed the distributors, who blamed the remanufacturers, who blamed the component suppliers for the poor product quality.

Evolution of the Cartridge Serial Number

The introduction of smart chips in the cartridges developed by the printer OEMs in the late 1990s became another hurdle for the aftermarket seeking to achieve a sustainable market share. They were often referred to as “killer chips” because they prevented the use of aftermarket cartridges that contained no chip or relied upon reusing the existing chip.

David Gibbons, the author of this article, ran his own remanufacturing business in the 1990s in Sydney, Australia. Gibbons claims the use of the chips by the OEMs posed a big threat for the aftermarket at the time.

As a printer cartridge remanufacturer in Sydney Australia in the 1990s, and as the executive office of the Australasian Cartridge Remanufacturers’ Association (ACRA), I remember well the threat chips were to aftermarket businesses. Remanufacturers argued the killer chips were a threat to “choice” for consumers who would be forced to use OEM cartridges only. But from an OEM perspective, the arguments fell on deaf ears.

The OEMs argued back at the time, and continue to claim, chips were to provide consumers with a better “customer experience.” Each printer cartridge is allocated a unique cartridge serial number, as is the case with any electronic product. The uniqueness of the serial number is used as an anti-counterfeiting measure, for example. The serial number in a cartridge also works in tandem with the printer to identify and communicate its manufacture date, place of origin, and other necessary information including the remaining level of toner. Cartridges can be traced and manage according to such unique identification.

Necessity is the mother of invention and the aftermarket moved quickly to find a solution with replacement chips that would work on remanufactured cartridges.

Most of the time, the investment into the development of replacement chips worked. Sometimes they did not work. The OEMs became more diligent and the science improved making it possible for more sophisticated chips to be developed.

In a “chicken and egg” scenario, remanufacturers blamed the component and chip suppliers, and the suppliers blamed the remanufacturers for the dilemma over the reliability and unreliability of available chips.

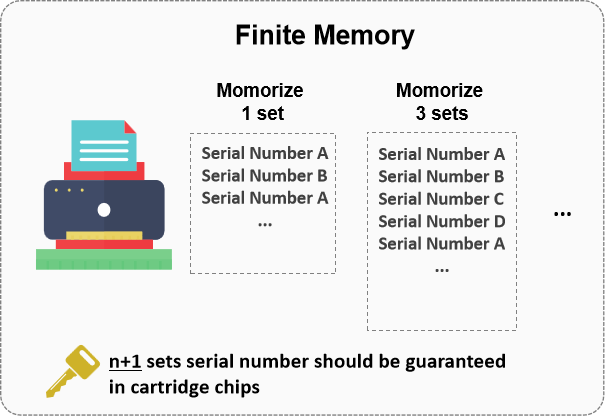

Chip manufacturers were forced to analyze the cause for the increasingly high rate of cartridge failures and found that some printers had the capacity to remember chip serial numbers. As a cartridge was installed into the printer, the serial number data in the chip was memorized by the printer. This meant that both OEM and aftermarket chips could not be reused. A printer would recognize the serial number of the cartridge as being the same serial number as having been used before. It would report an error and fail to work.

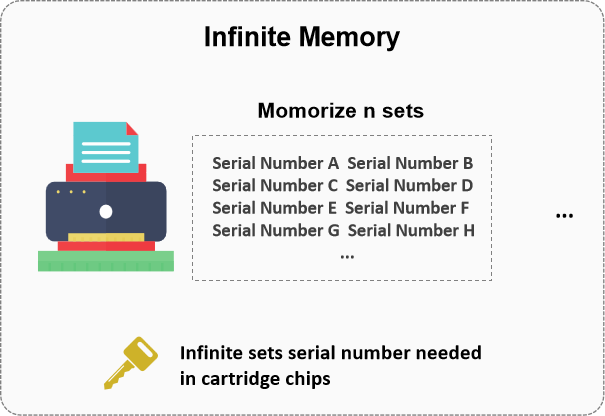

Chip manufacturer found at first, printers could remember a certain number of serial numbers of recently installed cartridges. With advances in chip technology, cartridge serial numbers developed from simple numbers to a specially encrypted code. This meant printers no longer needed to remember a certain number of serial numbers but were capable of remembering all serial numbers, permanently.

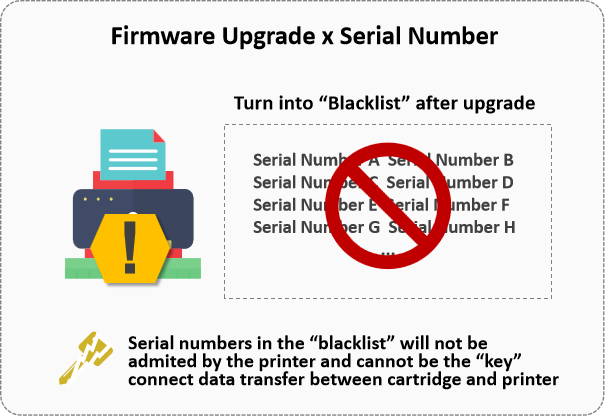

OEMs then developed a strategy where printers could have additional information passed on to each of their memories. This is through printer firmware updates and upgrades.

As has become well known, firmware updates can optimize performance, fix bugs and also change data instructions, raising the communication threshold between the cartridge chip and the printer. Once a printer is updated, it is enabled to block specific serial numbers, causing the replacement cartridges with a “blocked” serial number to be rejected by the printer.

The Cost and Risk of Chip Decoding

Chip design must conform to the printer’s memory mechanism so that serial numbers are recognized and accepted. Obtaining a plentiful supply of serial numbers is the key.

So, how does one get a plentiful supply of serial numbers? Remember, a cartridge serial number nowadays is no longer just an identification number but has to have the ability to be to a specially encrypted code when needed.

Developers of chips today have the ability to generate infinite serial numbers if the encryption algorithm has been decoded.

However, it is incredibly difficult to decode and redevelop an encryption algorithm. In general, chip manufacturers advise decoding times are measured in a number of years. The work required demands a huge investment in time and resources. It is arduous work and there are no guarantees it will provide a return on the investment.

Think of the amount of work and the financial risks that are being taken to develop a vaccine for COVID-19. Decoding a chip and developing a solution is a similar process, albeit on a different scale. But, the risk of reward is great, especially if the decoding and development time runs into a number of years.

However, is there another solution if chip manufacturers do not invest in the decoding of the encryption algorithm?

Yes, chip manufacturers can develop a massive number of serial numbers which will reduce the risk of installing replacement cartridges using the same chip serial numbers. This means, however, in order to generate sufficient serial numbers based on OEM cartridges, a chip manufacturer must be financially strong enough to purchase a plentiful supply of OEM cartridges and establish and maintain a professional lab containing data collection equipment for serial number decoding and development.

Even when a chip is developed, the risk is very high that if not enough serial numbers have been generated, some customers will find cartridges will still be rejected by their printers. Therefore, the chip manufacturer needs to constantly invest in order to maintain an ongoing, steady chip performance. This requires an enterprise to have sufficient resources invested to provide stable solutions for the market.

“The code is like a butterfly in the Amazon rainforest which, with each flap of a wing, causes a ripple of effects to influence chip manufacturers, cartridge manufacturers, end-users, and the entire aftermarket.”

Challenges and opportunities will continue to coexist into the future. The power of wisdom, backed up by an entrepreneurial spirit and investment, will deliver more “keys” and “fresh blood” to the sustainable development of the aftermarket. One thing is for sure: chips codes cartridges and printers will continue to be a hot issue.

Comment:

Please add your comments below about this article, “Chips Codes Cartridges and Printers.”

More articles from the author:

- Famous Sports Star Says Reuse is the Better Way to Recycle

- Famous sports star says reuse is the better way to recycle on a TV campaign promoting remanufactured cartridges with Australian cricket legend Mark Waugh.

- Bike Courier Services Boom in China During Coronavirus

- Bike courier services boom in China during the coronavirus and COVID-19 is delivering new opportunities but are westerners picking up?

- A Misplaced Australian in China – a different world view

- As a misplaced Australian in China, I had to learn quickly that many lies have been told about China and the role it has to play in world affairs. We should not reject China for all the preconceived opinions we may still hold. Rather, there may be opportunities here for you too.

- To Be? Or Not to Be? … But that’s NOT the Question

- The Aftermarket should be asking: “Is it infringing? Or is it not infringing?”

- What the Dickens?

- Charles Dickens, who was treated like a modern rock star, became incensed at how Americans were plagiarising his works.

- Chips Codes Cartridges and Printers

Excellent article! First time I saw so detailed history and analysis of Chips Codes. My compliments!