Coronavirus Lockdown and Now a Printer Lockdown

Coronavirus Lockdown and Now a Printer Lockdown

Coronavirus Lockdown and Now a Printer Lockdown

In the midst of the coronavirus pandemic, schools and colleges continue to be closed. Parents find their children having to stay at home during long periods of social distancing and lockdown. The home printer is getting a lot more use, churning out learning materials and work being done in the home-based classrooms. Out of the blue, the home printer stops working.

One original equipment manufacturer (OEM) has released a firmware upgrade over the internet that now blocks the printer from working with any cartridge that is not an OEM cartridge. With people already stressed by the upheavals caused by the coronavirus pandemic, wondering how they are going to find food now that supermarket shelves are empty, wondering whether they will lose their jobs, wondering whether they will have money to pay the rent or mortgage, wondering whether loved ones will catch the virus, and now this. Yet another complication that makes things so much harder to bear.

Should we really be expecting printer lockdowns in a time of coronavirus lockdowns? Let’s hope not, but what if they do happen?

Manufacturers often release firmware updates for their devices in order to make sure hardware is kept up to date with new technologies. With increased working from home prompted also by a coronavirus, some might argue it might be necessary to update technologies more often. In the case of printers, the firmware is installed directly to the printer and generally contains permanent fixes and features. Manufacturers usually recommend the latest firmware as this may provide significant enhancements to speed and functionality. However, once the firmware has been installed, the user is generally committed to that firmware until a new version is released. A firmware update can lock the installed printer cartridge, as well as subsequent third-party replacements stopping it from working the moment the update takes effect. Most inkjet and toner cartridges today are fitted with highly complicated encrypted devices that interact with the firmware in the printer and without this communication with the printer the cartridge will not print.

Firmware updates to printers that prevent the use of remanufactured, refilled, and compatible cartridges are nothing new. Such updates are beneficial from the point of view of OEMs, but they can be irksome to end-users who use aftermarket cartridges. For chipmakers and aftermarket cartridge manufacturers and resellers, OEM firmware updates are both incredibly disruptive and expensive. If a firmware update is serious enough, third-party chips must be redesigned, and cartridge manufacturers and resellers must replace cartridges with the old chip design with the new while fielding customer complaints about the old cartridges no longer working.

Firmware updates to printers that prevent the use of remanufactured, refilled, and compatible cartridges are nothing new. Such updates are beneficial from the point of view of OEMs, but they can be irksome to end-users who use aftermarket cartridges. For chipmakers and aftermarket cartridge manufacturers and resellers, OEM firmware updates are both incredibly disruptive and expensive. If a firmware update is serious enough, third-party chips must be redesigned, and cartridge manufacturers and resellers must replace cartridges with the old chip design with the new while fielding customer complaints about the old cartridges no longer working.

Let’s go back to that home classroom with the home-schooling printer on the sideboard in the dining room. The parents have been buying remanufactured printer cartridges ever since the printer was purchased. They have a limited budget and the remanufactured cartridges cost much less than the OEM cartridges. The students know that cartridges that can simply be refilled or remanufactured have a much lower environmental impact than the ones that are used only once and then discarded. The OEM releases the firmware upgrade. The printer is blocked from working with the remanufactured cartridge. An error message is displayed on the printer sitting on the sideboard: “cartridge problem.”

The parents, both of whom have now lost their ‘non-essential’ jobs in the coronavirus lockdown, during which a quarter of all businesses have closed, can’t afford food and rent, let alone pay for more expensive printer cartridges. There are several unused and unusable cartridges now sitting in the sideboard. The students check out the OEM’s website, which boasts world-leading sustainability and customer experience credentials. The language in that dining room when that printer went into lockdown cannot be repeated here for legal reasons.

What might the OEM say to the family in lockdown when a firmware upgrade is released and the use of remanufactured printer cartridges is blocked? The OEM might suggest that it updated a cartridge authentication procedure in select printer models to ensure the best consumer experience. The OEM might suggest that the firmware update was designed to protect its innovations and intellectual property and that its printers would continue to work with refilled or remanufactured cartridges with an original OEM security chip. The problem, of course, is that most third-party cartridges use third-party chips so as to offer fuller functionality and to avoid infringing OEM rights.

Sometimes the printer lockdown may be a result of a pre-set failure-date programmed by the OEM for non-OEM. The situation can be made more complicated because firmware upgrades can also be prompted by upgrades to computer operating systems. The activation of the pre-programmed firmware change can lead to situations in which customers are left with non-functioning printers and potentially a stockpile of unused (and unusable) aftermarket cartridges.

Meanwhile, back in the dining room, the parents and students are getting stressed. This ‘customer experience’ thing doesn’t add up. The students check the EPEAT website, which is how they identified what printer to buy in the first place. Manufacturers can register their printers and other products on the EPEAT website so that customers can check the environmental credentials of a printer before purchasing it. There it is in ‘black and white’, the printer sitting on the sideboard in the dining room is registered against two mandatory criteria:

Meanwhile, back in the dining room, the parents and students are getting stressed. This ‘customer experience’ thing doesn’t add up. The students check the EPEAT website, which is how they identified what printer to buy in the first place. Manufacturers can register their printers and other products on the EPEAT website so that customers can check the environmental credentials of a printer before purchasing it. There it is in ‘black and white’, the printer sitting on the sideboard in the dining room is registered against two mandatory criteria:

- 4.9.2.1 Allow use of non-manufacturer cartridges and non-manufacturer containers

- 4.9.4.1 Documentation that the cartridge or container is not designed to prevent its reuse and recycling

These are two of the criteria that were developed through a multi-stakeholder effort that led to the development of the IEEE 1680.2 Standard for Environmental Assessment of Imaging Equipment (amended), the mainstay of the EPEAT Product Registration system for imaging equipment. Stakeholders included OEMs and representatives of the remanufacturing industry (such as UKCRA and ETIRA) as well as many other organisations and interested parties (listed in the Standard).

The EPEAT system allows for product registration according to Bronze, Silver and Gold ratings, with the highest ratings requiring greater levels of environmental performance. For example, a printer registered under the EPEAT environmental standard is required to be designed (criterion 4.9.4.1) so that the cartridge or container is not designed to prevent its reuse and recycling.

Surely, a design modification to a printer, such as a firmware upgrade, that changes the compliance status of the printer with EPEAT qualification criteria effectively invalidates the registration of the printer?

Surely, a design modification to a printer, such as a firmware upgrade, that changes the compliance status of the printer with EPEAT qualification criteria effectively invalidates the registration of the printer?

The EPEAT registry is seen by OEMs as an important means of informing potential purchasers of the environmental credentials of their printers (and other electronic equipment). Some purchasing organisations, for example, will only purchase printers (and other equipment) qualified to a particular EPEAT level (e.g. silver or gold) and so an OEM product that has not attained such registration will not be purchased. Compliance with consumer protection and anti-trust frameworks are of vital relevance to all stakeholders in the EPEAT endeavour. A product registration that continues to be displayed on the registry but which has been rendered unqualified through firmware upgrade is one that potentially gives grounds for claims of misleading advertising.

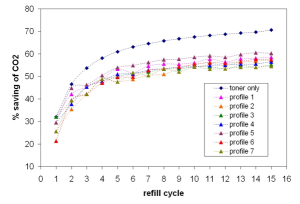

Back in that dining room, the students have downloaded a paper on the carbon footprint of remanufactured cartridges compared with OEM cartridges. Each time a printer cartridge is remanufactured (and refilled with toner), one or more of its components may be replaced, although in some refill cycles no components need to be replaced. In Figure 7 of the downloaded paper, the reduction in the carbon footprint of the remanufactured cartridge compared with that of the manufacturer’s original cartridge is compared. After several cycles, the reduction in carbon footprint has stabilised at about 50%.

Figure – percentage saving in CO2 emissions of remanufactured cartridges relative to OEM cartridges.

It is no wonder the family in coronavirus lockdown are concerned about the manufacturer’s lockdown of their printer. They purposefully chose an EPEAT registered printer thinking that it would be able to use remanufactured cartridges, which are cheaper than manufacturer’s original cartridges and which have much lower carbon footprints.

How might remanufacturers be affected? Consumers may return remanufactured printer cartridge products designed for OEM printers. The pre-programming of updates makes it harder for remanufacturers to produce chips that work for the consumer to have confidence in their purchasing decisions and their (corporate) social responsibility intentions. The pre-programming of updates undermines the process of provision of warranty by the remanufacturer on the remanufactured cartridge. This undermines aspirations to develop warranty frameworks for the circular economy. It is noted that according to Regulation 74 of the WEEE Regulations 2013 an emphasis on producers not preventing “through specific design features or manufacturing processes, WEEE from being reused, unless such specific design features or manufacturing processes present overriding advantages, for example, with regard to the protection of the environment or safety requirements”.

Clearly the family mentioned in this article is fictional, and the firmware upgrade to the family’s printer is fictional, but the issues raised are not. The remanufacturing industry is a well-established industry that addresses a gap in the OEM business model, i.e. the lack of coverage of the remanufacturing stage in the product life cycle, and directly meets customer needs for products with reduced environmental impact and lower cost. The remanufacturing industry relies on the supply of used cartridges into the market. Without their availability, the remanufacturing industry would not have the feedstock on which it relies. In a time when so many parts of our societies are coming together to address the turmoil and distress caused by the coronavirus, there is the opportunity for the imaging equipment and consumables industry to work together to avoid creating further challenges. There is an opportunity through the economic shock that is being triggered by the coronavirus pandemic for manufacturers and remanufacturers to reconsider how they work together to improve the ways in which they provide socially and environmentally preferable goods and services. Even when the coronavirus emergency is over, we will still have the climate emergency to deal with. Companies will be judged and remembered by the decisions and actions they take during this very difficult time.

Related:

- HP Continues its Despicable Treatment of Customers

- Latest Despicable Trick by HP Exposed

- This article is also published in our magazine. Click to download the magazine for free.

Comment:

What are your thoughts on this article, “Coronavirus Lockdown and Now a Printer Lockdown” by Michael Gell (pictured)?

Please add your comments below or in LinkedIn on social media.

Leave a Comment

Want to join the discussion?Feel free to contribute!