Examining the Quality of Toners

There have been recent reports about the bad quality and health consequences of Chinese produced toner. Where does bad quality come from?

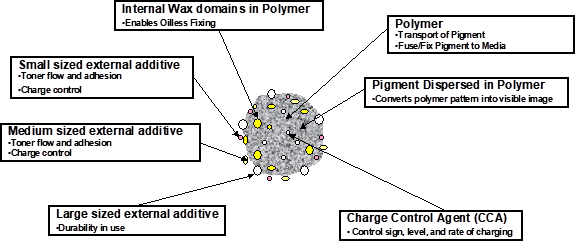

Just as with any product from any country, the quality of toner depends on the manufacturer of that product and the decisions that are made by the formulator, and the purchasing and manufacturing departments. The composition of any powder toner consists of pigment, polymer, wax, charge control agent, bulk additives and surface additives.

In general, lower-cost raw materials, wherever they are sourced, are likely to contain “impurities” that could possibly be undesirable from a health and safety perspective. A variety of such trace materials have been identified as potential health hazards in toner. One category of the materials of concern includes Volatile Organic Compounds (VOC) – including Styrene, Benzene, ethylene glycol, formaldehyde, methylene chloride, tetrachloroethylene, toluene, xylene, and 1,3-butadiene.

Such materials, if present in toner, can be released into working the environment during the fusing/fixing stage of the print process. As the toner that is transferred from the photoconductor to the paper or other substrate is heated reaching 130 to 180°C any VOC content of the toner is volatilized and exhausted from the print engine by the machine cooling system through the fan and duct to the space in which it is being operated.

Other sources of environmental pollutants from toner are toner dust and loose toner surface additives. All toners comprise finely divided particles that have a mean particle size of anywhere from five to ten microns. This mean is only the middle point of the toner particle size range, and toner can contain particles of size well below five microns and well above ten microns

The removal of particles from any source of dust that penetrates into the gas exchange region of the lungs depends on a variety of factors but significantly depends on the diameter of the particle. Hazardous particulate size is primarily less than five microns, and particle sizes of 2.5 microns (PM2.5) are often used in the U.S. to describe non-respirable dust. The particle size distribution (PSD) – the range and percentage content of toner particles by the size of any toner – depends on the toner composition and the toner production conditions. With respect to toner dust less careful, and typically lower-cost manufacturing can be responsible for toners that “dust”. Such toners might have a mean particle size that matches that required for operation in a particular engine. but have a psd that is too broad or has a high fractional content of ultra-small-sized toner particles.

In addition, the surface additives that are used to promote toner powder flow, durability and charging need to be processed in the production of the toner such that they are sufficiently well attached to the toner particle surface to prevent their release from the surface of the toner particles during the entire printing process.

This process is highly agitating: starting with the agitative processes in the print engine of delivery from the toner reservoir, application to the developer roller, transfer to the paper or substrate and on to the downstream processes of printing. The typical surface additives used in toner are ultra-small in size compared to the toner, with sizes ranging from eight to 250 nanometers, well below the PM2.5 particle size considered to be dangerous from a respirability perspective. Typical materials used include silicon dioxide, aluminium oxide and titanium dioxide.

In addition to the dust respirability factor, there has been recent attention to the question about the foregoing gives some idea of the range of issues regarding the development and manufacturing of toner, and these matters concern all toner manufacturers worldwide. That the manufacturing of toner, particularly for the aftermarket, has shifted geographically from Europe and North America to Asia brings the focus to that region. Production in China is, of course, an important development of this trend. The other aspect of this shift is that there has been the development of raw material supply in Asia in support. Sources of locally manufactured toner ingredients have been established and developed. Some of those companies are new to the toner manufacturing industry and have been on a “learning curve” regarding the requirements for materials for toner.

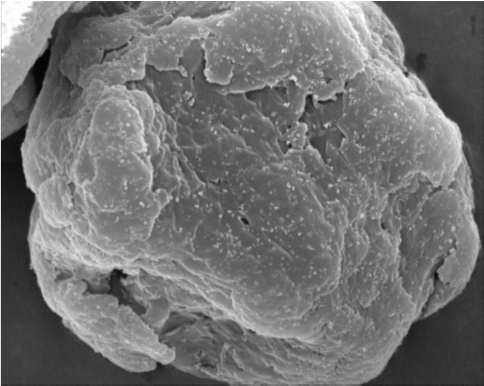

the effect on the health of ingestion of titanium dioxide. The scanning electron microscope (SEM) picture below shows surface additives as very small white dots on the toner particle.

With this geographical shift, new manufacturing capacity, as well as transferred production capacity, has been established. Simultaneously, there has been a constraint on production caused by softening of demand, particularly for types of toner most popular in the aftermarket. This imbalance in the “push-pull” between the available capacity and market demand has generated severe price competition and depressed profitability in the toner manufacturing industry, particularly in the more recently developed toner manufacturing in Asia.

The natural response by toner manufacturers in attempts to mitigate this is to economize and attempt to reduce unit cost by reducing raw material and manufacturing costs. For some manufacturers, this means that they are using lower quality polymer, pigment, magnetite, wax, and other ingredients and increasing production throughput rates with consequential degradation of PSD and integrity of the toner and its additives.

In general, but not universally, lower cost raw materials, and the use of raw materials, that are not designed for toner use, results in issues of high VOC content and content of undesirable trace materials. The changes made in raw material compounding conditions to increase throughput rate resulting in higher heat and energy input can cause degradation of raw materials and the creation of VOC fractions.

Higher production throughput rates in fine grinding to reduce energy cost content per kilo and changes to classification to maximize product yield, both strategies to reduce product cost potentially increase the likelihood of “dusting” of toner in use.

There is no such thing as “Chinese Toner” as a homogenous set of products. As has always been the case in the toner industry, irrespective of the location of manufacture, there are within toner manufacturers professionally oriented, responsible manufacturers, which develop and manufacture their products responsibly with the objective of maintaining standards of performance and minimization of any environmental or health impact.

There are also those companies that do not follow the same policies. It is important in any purchasing decision, whether as a reseller or user, that the full cost of purchase rather than the price is considered, as poor quality can significantly impact the cost. The efficacy of Chinese toners just like toner from any other geographical regions vary. Not all are bad or good. Buyers should be conscientious in their evaluation of products before they purchase.

Leave a Comment

Want to join the discussion?Feel free to contribute!