Meeting the Market’s Changing Demands – 5 Questions for Bonell

Meeting the Market’s Changing Demands

I caught up with Static Control’s Juan Carlos Bonell following his acceptance of the 2019 Supplier of the Year Award at the Annual Global Industry Awards. I wanted to know how the imaging supplies industry is being impacted by the evolution of customer demands.

I asked Bonell five questions:

1. What is your industry background?

I joined Componentes de Colombia as general manager more than 15 years ago. In 2006, Static Control hired me to develop the Mexican and Chilean markets. I eventually became the vice president of sales for our global distribution in Russia, India, the Middle East, Australia, Japan and North Africa as well as all of Latin America.

2. What transition is SCC making to extend its brand into finished products?

We proudly continue our more-than-30-years’ brand reputation by serving our global remanufacturing customers with quality products including toners, components and chips.

At the same time, many of these same customers, under a lot of price pressure competition from the entrance of new-build cartridges (NBCs) into their markets, are asking for our support to deliver a premium quality, finished product that would differentiate them from the large offering of NBCs in the market.

We have evolved by taking our market-leading know-how about producing and selling high-quality chips, components, toner and other imaging solutions and launched our own premium quality, finished cartridge products that are considerate of IP and provide customers with a reliability that is unmatched in this industry.

3. What technical and market perception problems about new build compatibles (NBCs) have been resolved?

Over the past five years, we have identified many inconsistency issues related to the various business models used by manufacturers in China. Some factories would dramatically increase the production volume in order to decrease their cost per unit and therefore, decrease the cost to the customer. Many of those factories also changed its Build of Material (BOM) to lower quality materials in order to have continued production.

We have worked hard to solve those issues with our manufacturers from the outset: to create a BOM that delivers a premium level of performance. Nor do we accept BOM variations. We protect our customers from those quality variances to make sure they receive the most consistent product in the industry, the same way we have been delivering on our component products for years.

We have also implemented an APQP (Advanced Product Quality Planning) quality control process of strict procedures and techniques that were created for the automotive industry. Our own quality engineers in the factories ensure products meet our specifications.

4. Is SCC able to deal with the OEM firmware upgrade strategies to lockout third-party consumables?

Our chip development group has made our chips the most firmware resistant in the market. New firmware changes impact more than just the chip, but also the cartridge quality.

We have a unique advantage because we are pioneers in dealing with firmware changes and understand the OEM technology better than any other aftermarket competitor. Our cartridges and chips can keep up with these changes and avoid the frustration and bad customer experiences from end-users that occur with other suppliers.

5. Do international buyers still buy on price alone, or is there a shift towards quality and an awareness of IP rights?

The entrance of NBCs into international markets was solely driven by price and that’s how the NBCs displaced the remanufactured products and gained a strong market share— 60% of the market in countries like Brazil and growing by double digits in other international markets, like Russia.

The distribution channel (wholesalers and dealers) are more sensitive to quality changes and are demanding better products for end-users. Consequently, the larger importers and traders prefer to keep the same suppliers to avoid issues with their products and the supply chain.

IP rights are more of a concern in regions like the US and Europe, but recently there have been more OEM actions in emerging markets like Russia and Brazil where the aftermarket dominates the market.

Static Control looks forward to growing and finding more companies to partner with to offer the necessary quality and reliability to thrive.

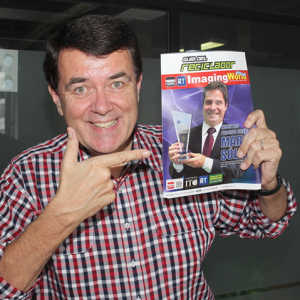

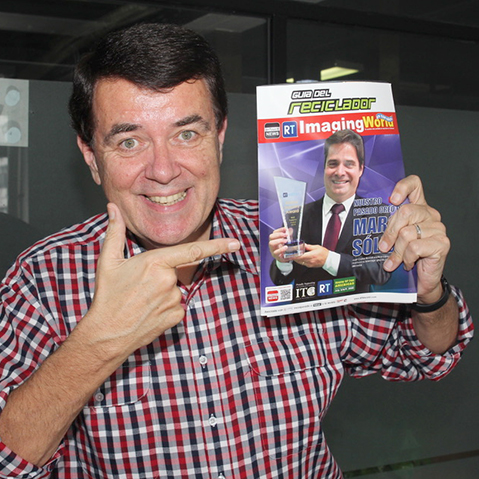

RT director and publisher, David Gibbons receives the first copy of the magazine from the printer featuring Juan Carlos Bonnel on the front cover

Bonell is also featured on the front cover of the Spanish language edition of RT ImagingWorld magazine. You can download a copy here.

Bonell is also featured on the front cover of the Spanish language edition of RT ImagingWorld magazine. You can download a copy here.

The photo on the cover depicts Juan Carlos Bonell accepting the Best Global Supplier of the Year Award on behalf of Static Control Components, in Zhuhai, China.

If you are wanting to know more about meeting the market’s changing demands, contact Bonnel by email at <juanb@scc-inc.com> or on LinkedIn

Leave a Comment

Want to join the discussion?Feel free to contribute!