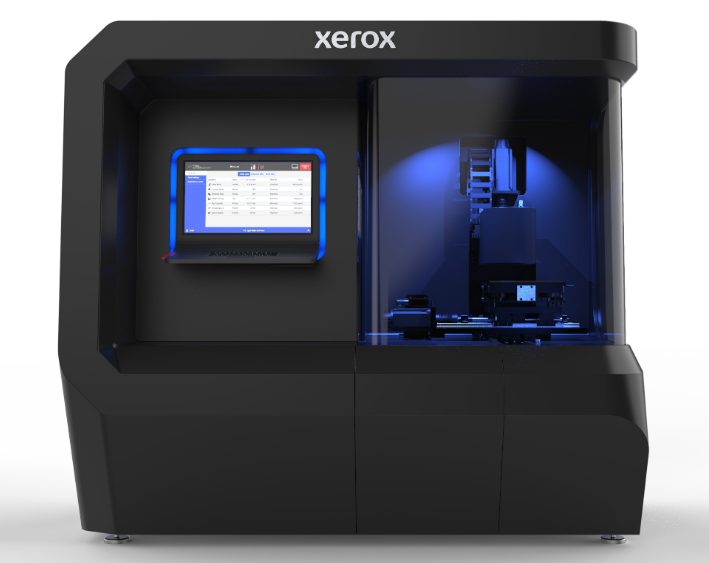

Xerox Debuts 3D Liquid Metal Technology

Xerox aims to disrupt traditional manufacturing through its 3D liquid metal technology combined with AI-based design software. “By pairing these two technologies, manufacturers will be able to design and fabricate parts that meet their structural and cost requirements on the first try,” said Xerox Chief Technology Officer, Naresh Shanker.

Previously, Xerox debuted its 3D liquid metal prototype at the Formnext conference in Frankfurt, Germany.

To meet business needs for on-demand products, Xerox 3D printing technology uses liquid metal printing to decrease production time from days to hours. And Xerox 3D metal printers use off-the-shelf alloys—the same alloys used in traditional manufacturing, allowing manufacturers to design parts using materials they already know. This means parts are denser, faster to make and less expensive than those made with metal powders.

Xerox’s AI-based 3D software integrates all steps of fabrication from design to manufacturing planning and performance analysis, allowing for consistent part quality and customization.

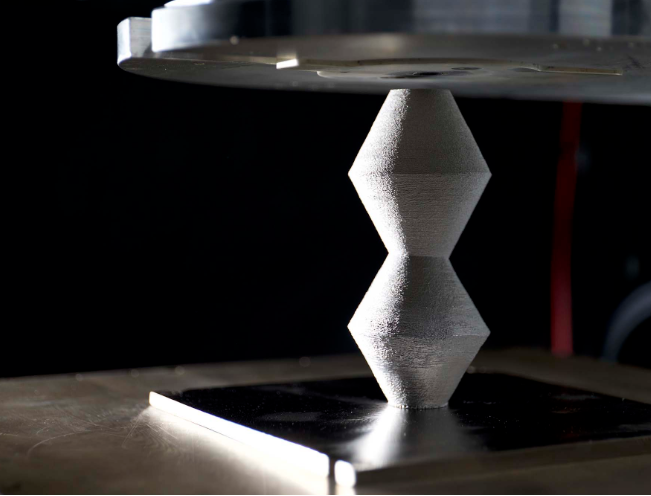

An item printed by Xerox using liquid metal technology.

“Using 3D printing to make unusual geometric parts out of lightweight materials, like high performance polymers, or composite materials, means you can offer an improved product,” says Core. In the auto industry, for instance, the technology can allow carmakers to replace traditional parts with lighter-weight versions and shave weight off vehicles. That can substantially lower fuel costs and carbon emissions over the lifetime of a car.

“We are about to enter the most disruptive era in manufacturing since the Industrial Revolution, thanks to additive manufacturing,” writes Doty.

(Source: https://www.xerox.com/)

Related readings:

Leave a Comment

Want to join the discussion?Feel free to contribute!